Patch

Patches, badges, patches, embroidered badges, there are many terms used to refer to an application often used on the outside of garments, to customise and enrich jackets, outerwear, trousers, sweatshirts, knitwear…

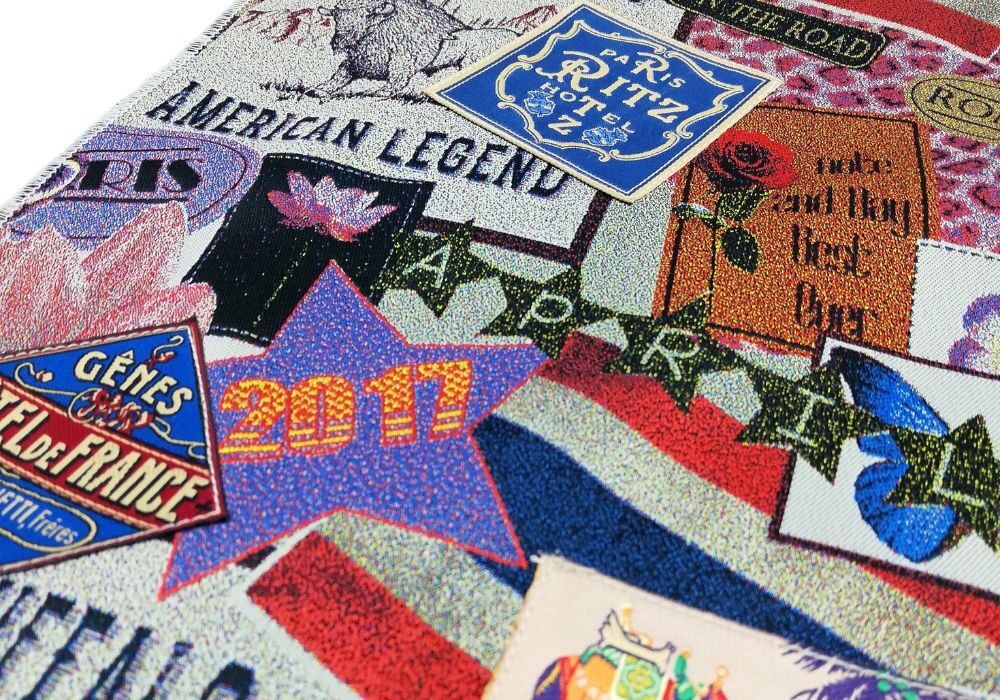

Woven patches

The first stage of the production process is the same as for the jacquard woven label, with the difference that the patch weaves are specially designed to give a three-dimensional appearance and a more solid, rigid and often voluminous structure. Sometimes the position of the application on the garment or even just aesthetic taste may require an embroidered outline, which gives even more character to an article that is already attractive and precious at the same time

Features

Shape and size +

Without any limitations are the prerogative of our patch shaping machines.

The precision and versatility of our laser equipment allows us to execute the most complex shapes without ever compromising profile accuracy.

SUPPORT OF VARIOUS TYPES +

After weaving, the patches are laminated with a variety of materials, thermoadhesive, double-sided, non-woven or any other textile material.

If required, they can be laminated with Velcro at the seam to be applied or detached as desired or as required by the end user.

Use +

Unlike embroidered patches, jacquard allows any small writing or graphics to be reproduced without compromising accuracy.

Embroidered patches

We produce embroidered patches of any shape and for any type of application, using any support required, any material, from leather to fabric, with metal or jacquard inserts, in order to provide a product that is always innovative and can always enhance the identity of the brands that rely on our skills.

Features

Support +

Any support required for the need for applications.

Shape and size +

Only limit: imagination.

Sustainability +

We can always use innovative but above all sustainable support materials.