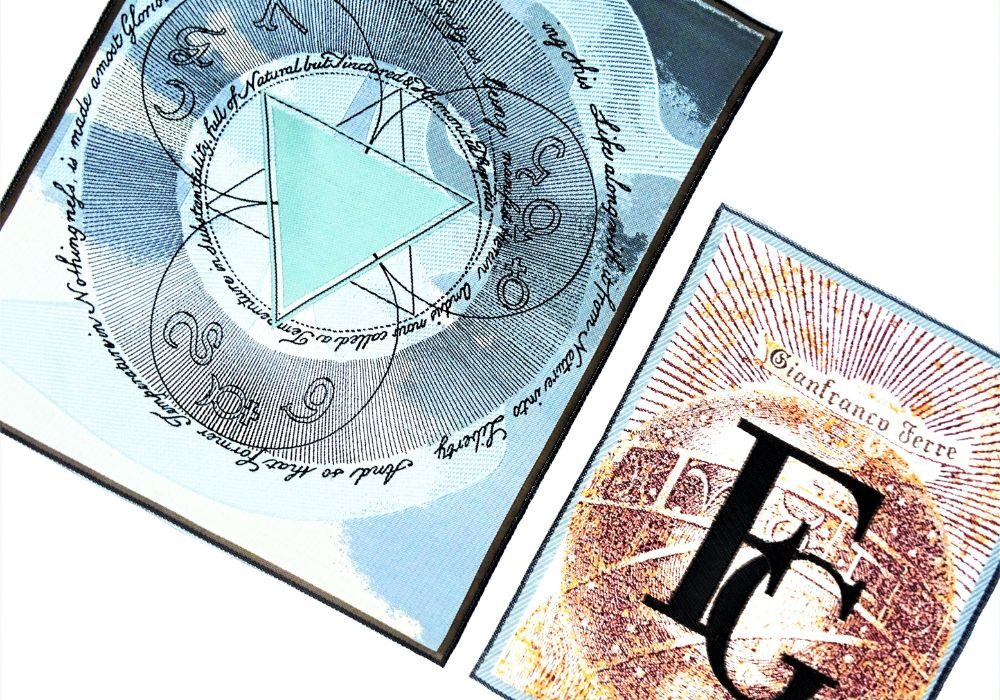

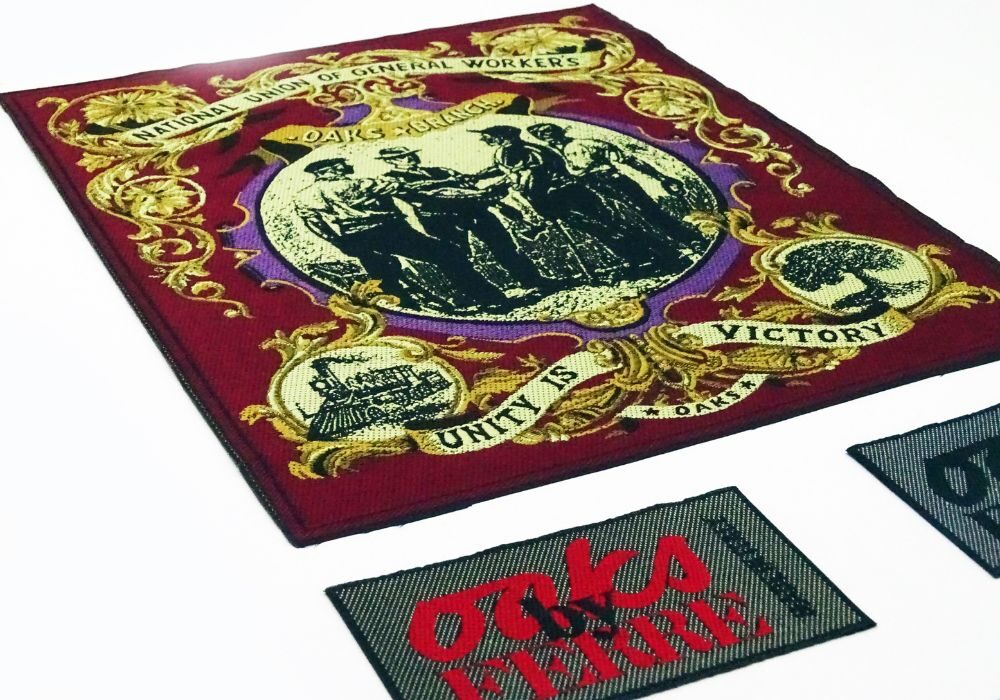

Woven labels

At Decatex, we are committed to supporting our customers from the earliest stages of the design process, offering tailor-made solutions to ensure the smooth placement of labels on garments. Our design department, ‘Ddesign’, takes care of creating eye-catching graphic proposals, accompanied by appropriate colour palettes. After thorough consultation, we move on to the textile phase, providing samples for final approval, with colour variations, before proceeding with final production.

Heat-sealed and ultrasound

Our looms process up to 12 different wefts simultaneously, which intertwine with the warp to produce unlimited colours and nuances. Yarns can be woven as fine as a hair and as thick as a twine, be cut by heat or ultrasonic technology for a soft, supple edge. They can be low definition with a slightly retro inspiration or high or very high definition to reproduce even the smallest details. We have all the traditional settings for label looms: taffeta, satin and rasetto.

Features

Compositions +

Usually 100% polyester with the possibility of inserting any other recycled, natural, artificial fibre.

Size and dimensions +

From 5 mm up to 1500 mm in height with no limit. In practice, the dimensional solutions are unlimited

Packaging +

Folded or cut in the middle or on the sides, mitered, cavallotto, asymmetrical, they can be laminated with special double-sided and thermoadhesive materials By virtue of our textile experience and design and creative sensitivity, we can assign different weaves to clothing labels depending on the desired result: soft, light, soft, rigid, heavy, flat, smooth, thin or bulkier, etc.

Waved labels

By virtue of our textile experience and design and creative sensitivity, we can assign different weaves to garment labels depending on the desired result: soft, light, soft, stiff, heavy, flat, smooth, thin or bulkier, etc.

Features

Compositions +

The article can be made of 100 per cent silk or 100 per cent cotton or 100 per cent polyester, or in a variety of weaves.

Size and dimension +

With the tools at our disposal, we can meet any size requirement. From a minimum of 8 mm to a maximum of 200 mm, depending on usage requirements.

Packaging +

Cut and welded or folded in the centre or on the sides, mitered, cavallot, asymmetrical can be laminated with special double-sided and thermoadhesive materials with a soft, light, soft, hard, heavy, flat, smooth, thin handle.

Shuttle labels

Shuttle labels

The most exclusive of labels, with a sartorial taste and flavour, the selvedge is made by the loom that constructs it during weaving, guaranteeing its quality and softness.

Features

Compositions +

Possibility of using any type of warp and weft (silk, cotton, ...)

Number of colours +

The loom is capable of weaving a background weft and two brocade colours.

Applications +

Both tapes and labels can be obtained.

Rfid and

anti-counterfeiting

Digitisation pushes production processes to be fast and flexible, and the use of Rfid supports these processes by speeding up storage management and product tracking from production to the end user.

There is also the possibility of

Customised project +

From label type to final tracking

Support +

Various types of media, textile or paper.

use +

Collaboration with the customer to study the most functional method of insertion on the garment for the intended purpose.

Dai uno sguardo da vicino

Tubulars

and pullers

The article that increasingly completes the customisation of a purely sporty garment, but not only, is the zip puller.

The umpteenth distinctive touch of a product that wants to be cared for and refined down to the smallest detail. In addition to facilitating the use of the zip itself, it adds an aesthetic-functional element to the garment.

The customised zip pull can be simple or double (logos and texts on the right and reverse),

The two sides are to all intents and purposes independent, both in colour and graphics

The Decatex technical department, with the collaboration of the Ddesign graphics department, has developed different production methods that allow the zip puller to be adapted to each type of zip according to its position and, above all, to the customer’s requirements.

Features

Shape and size +

The classic tirazipp is typically between 10 and 13 mm wide, but there are no dimensional limits. It is abiatully rectangular in shape but can be shaped as desired.

With buttonhole or sewing +

It is possible to engrave a small cut with laser technology that allows for choker insertion into the slider, alternatively a flat part is reserved in the weaving for use with stitching.

Inflated or flat +

The tubular structure facilitates the inflation of the tirazipp, which is a sportier alternative to the flat version. Both the flat and the tubular solution provide the possibility to process the front and back of the article independently.